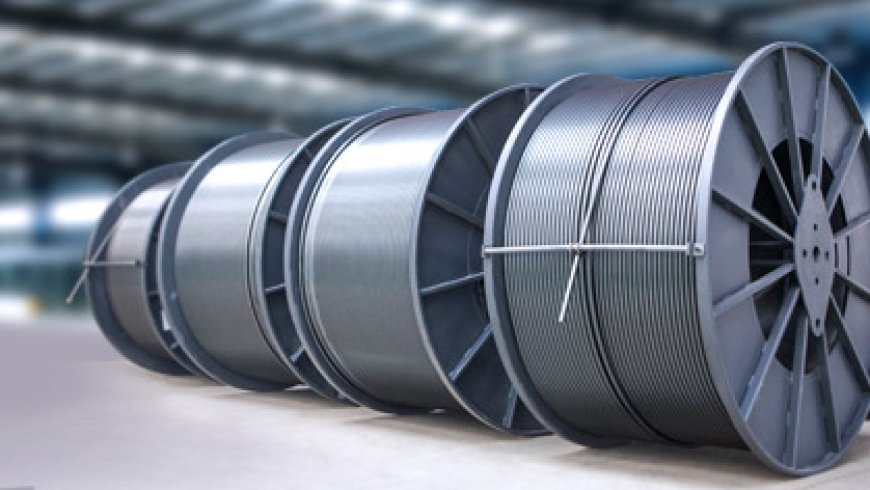

Why Do You Need a Coiled Tube?

This piece by the coiled tube manufacturers explores the physics and advantages of coiled tubes to an amazing level of detail, looking at their far-reaching uses and how they're critical to systems of industry and business today.

In production, engineering, and fluid flow, a small design element can make a giant difference in system performance. One of those unsung heroes, one guesses, is the coiled tube: an appallingly simple but blessedly effective component of everything from air conditioners to laboratory instruments and hydraulic systems. It appears at first sight simply a tube bending into a coil, but its application is significantly more than usability. So why in the world would you ever use a coiled tube?

The response is found in the distinctive combination of space-saving, heat management, flexibility, and vibration damping. This piece by the Coiled Tube Manufacturers explores the physics and advantages of coiled tubes to an amazing level of detail, looking at their far-reaching uses and how they're critical to systems of industry and business today.

What is a Coiled Tube?

Coiled tube is simply a coiled tube in the form of a helix or a spiral and employed as a tube of significant length. They can be of any material, such as stainless steel, copper, plastic, or alloy metal, depending on use. They are unlike straight tubes since they incorporate more space-saving installations, tube lengths of larger length for fewer spaces, and more functionality like heat transfer or pressure regulation.

The Most Critical Reasons Why You Require a Coiled Tube

1. Efficient Heat Exchange

The most significant use of coiled tubes is in heat exchangers. The coiled nature offers more surface area to the heat exchange surface/fluid/environment surrounding it, thus the thermal exchange efficiency. In cooling or heating systems needed in, say, condensers, evaporators, or radiators, the coiled nature offers an efficient means of dissipation or absorption of heat.

Coiled tubes are employed in industrial processing equipment or air conditioners for the principal function of preserving working temperature at efficient and safe levels. Copper or stainless steel coils, for example, are employed in significant quantities in refrigerating equipment to achieve optimum cooling capacity.

2. Space Optimization

An unwound tube of equal radius is a much bigger object and hence not a suitable candidate to put into the relatively tiny environment. Spiral tubes are very thin in cases where the space is tightest, i.e., on-board equipment, medical equipment, or parts utilized by airplanes.

Coiled configurations allow for the placement of more tube lengths inside limited space without loss of fluid volume or flow. This is invaluable in space-limited applications like oil & gas or marine.

3. Flexibility and Stress Absorption

Compared to the straight pipes, the coiled tubes possess inherent flexibility, due to which they are able to withstand the thermal expansion as well as vibration. In high-temperature or high-pressure systems, flexibility serves as protective armour for stress concentration damage.

For instance, in thermal expansion and contraction in hydraulic fluid or in boilers, it results in cracking and leaks. This is prevented by the employment of coiled tubes that have flexibility and the capacity to allow for some movement in the coil itself, thereby making the system more long-lasting and reliable.

4. Enhanced Flow Dynamics

Turbulent flow, created by coiled tubes in other shapes, is used to optimal benefit in heat exchangers. Turbulent flow is preferable in heat transfer rate over laminar flow in a straight tube. In drug or food processing equipment, where continuous temperature is required to be supplied, coiled tubes provide equal thermal conditions to the product.

Also, coiling motion through the pipe can assist in fluid mixing or prevention of settling, characteristic of long, straight pipes.

5. Pressure and Safety Control

Coiled tubing incorporates a pressure control system built into high-pressure operations. The additional length of path through the coil offers even pressure droop with less chance of pressure drop or pressure surge.

Coiled tubes are also applied as a safety device in use in fuel lines, pressure vessels, and steam boilers. Coiled tubes can even be used as pressure dampeners to eradicate variations to achieve steady flow.

General Application of Coiled Tubes

It is not so hard to be amazed at the diversity of coiled tubes if one only thinks of the numerous applications in all industries:

? HVAC Systems: For temperature control and heat transfer.

? Medical Equipment: In anaesthetic machines and oxygen concentrators to detect proper gas flow.

? Petrochemical Industry: For fluid transfer under diversified pressure and temperature conditions.

? Food & Beverage: In breweries, distilling equipment, and pasteurizers.

? Automotive Industry: For fuel hoses, brake hoses, and vehicle cooling transportation.

? Lab Equipment: Used in chromatography or gas sampling where accuracy is the issue.

? Power Generation: Where temperature and pressure control are most critical in steam turbines and nuclear reactors.

Materials used in Coiled Tubes

A coiled tube will function largely based on the material. Some of the most common and why they can be so useful are as follows:

? Stainless Steel: Unmatched corrosion and heat resistance. Extremely well suited for chemical and food processing use.

? Copper: Improved heat transfer, thus optimally used in refrigeration and HVAC applications.

? Titanium: Great corrosion resistance and high strength-to-weight ratio, normally suited for sea or medical use.

? Plastics (i.e., PTFE, Nylon): Either for low-pressure tubing or chemical resistance laboratory uses.

The material would be based on the thermal range, pressure rating, and chemical compatibility of the system on which the coil will be installed.

Conclusion

The next time you see a corkscrew tube on an industrial machine or system, pay attention to what it isa work of engineering art.

Its corkscrew shape is not there for show or convenienceit's to provide design functions that are essential to system performance, reliability, and efficiency.

Whether you're creating a high-tech air conditioning system, a high-capacity laboratory equipment system, or a high-duty industrial fluid system, the coiled tube is the solution for space savability, heat management, vibration dampening, and fluid management. Out of sight, but never out of mind. So, yes, you do need to use a coiled tubebecause sometimes it's the small things that can make big things happen.

Also Read: What Do Wires and Cables do in Mining Operations?